Micropiles are one of the most financial and in some cases just solution in challenging ground problems and also limited gain access to. For sites that have extra identical dirt accounts, various other structures such as auger cast heaps or driven stacks are preferred. Micropiles are normally made use of when there are difficult ground problems, such as all-natural or man-made blockages, delicate ground with nearby frameworks, limited access/low headroom and/or karstic geology. In drilled pier foundations, the piers can be gotten in touch with grade light beams on which the framework sits, occasionally with heavy column tons bearing directly on the piers. In some property construction, the piers are expanded over the ground degree, and wood beam of lights bearing upon the piers are used to sustain the framework. This sort of foundation results in a crawl room below the structure in which wiring as well as duct work can be laid during building or re-modelling.

What is the quantity of pile?

For these buildings, a stack foundation is the best method to lessen ground vibration. Larsen Foundations Ltd has a number of budget-friendly minipiled underpinning services. Our most popular limited accessibility minipiled underpinning services are outlined below. Traditional Support is generally applied when the existing structures are at a superficial depth. It is economical if lots bearing strata can be found at a depth approximately 1.5 m.

Bigger Bar Micropile Expense Saving Benefits

The advantage is that the building and construction trouble is low, specifically for hand-dug piles, which can be without the limitation of the variety of makers as well as save time significantly. The disadvantage is that the bearing capacity is reduced and it costs products. An augercast heap, usually known as a continual trip augering heap, is created by drilling into the ground with a hollow stemmed constant trip auger to the needed depth or degree of resistance. While the cement grout is pumped, the auger is slowly taken out, conveying the soil upward along the trips. Recent developments in addition to strict quality control enables reinforcing cages to be placed up to the full size of a pile when needed. Micropiles are frequently evaluated in compression as well as stress for confirmation and evidence examinations.

The Wild Side of Town – Texas Monthly - Texas Monthly

The Wild Side of Town – Texas Monthly.

Posted: Thu, 30 Jun 2022 17:37:33 GMT [source]

Furthermore, micropiles can be mounted with preexisting foundations and for the underpinning of frameworks as well as fixing of faulty structures. A micropile is a high capability little diameter stack that can be mounted with challenging soil conditions and in limited gain access to. Micropiles are generally installed by progressing casing pipeline to rock, piercing a rock socket, then grouting reinforcing steel in the rock socket. Micropiles are high-performance, high-capacity drilled deep foundation elements normally between 5-- 12 inches in diameter that can reach midsts of 200 feet and achieve workload of over 200 bunches. Micropiles are included high-strength steel covering, rebar as well as grout. Gibson constructs mini-piles by piercing tiny size openings and also building piles with high tensile steel as well as high compressive strength grouts to achieve tremendous load bearing capacities.

Example: Calculating The Capability Of Piles In Sand

Accepted by the FHWA in the Micropile Layout and Building Standards Guidebook, Hollow Pubs are being used increasingly for micropile applications. Via the enhanced bond tension resultant from the simultaneous boring as well as grouting procedure, Hollow Pubs are the reinforcement bar choice in breaking down soil problems. Depending on ideal ground problems they can be installed in a cost-efficient method, with high tons bearing capacities. Huge accuracy instrument producing such as here buildings with extremely high needs for developing stability.

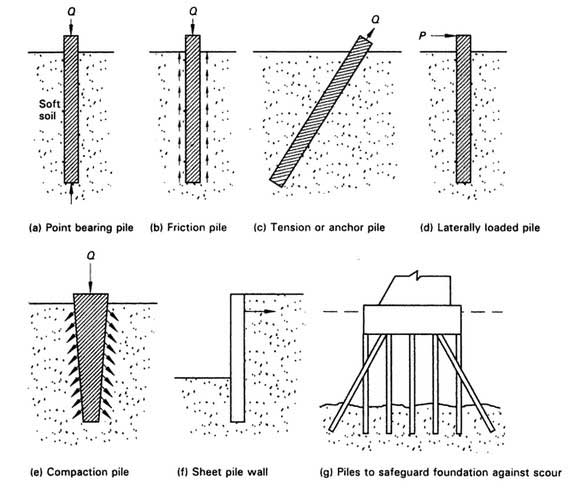

- To conveniently comprehend the tons transfer mechanism of a single heap, imagine a concrete heap of size L with size D, as displayed in Figure 1.

- In some property construction, the piers are prolonged over the ground level, and also timber beams bearing on the piers are utilized to support the structure.

- Reinforcing steel, generally an all-thread bar is placed into the case.

- Under reamed heaps are made use of, Where lifting pressures appear at the base of foundation.

The stack is compacting the ground along the side boosting the soil density, which also enhances the bearing capability. Micropiles are the best deep foundation system in challenging karst geology. In Subsurface Building and construction's solution area, karst is found in the mountains of Virginia and eastern Tennessee.

Drilled right into bedrock, micropiles or minipiles bond to the rock socket wall for lots transfer. Pierce gears mini piling contractors in north west for micropiles might be man-portable for confined interior installations or as much as 40 heap tracked equipments for big structure websites. Micropile systems are chosen to sustain and stabilize structures, bridges, freeways, towers as well as various other man-made structures, either as new foundations or remedial construction. They are also frequently used for foundation and also shoring applications due to their high lots ability and flexible installment strategies.

“Smashed:” Record month in store for Tesla sales as seventh ship arrives - The Driven

“Smashed:” Record month in store for Tesla sales as seventh ship arrives.

Posted: Tue, 30 Aug 2022 07:00:00 GMT [source]

Today, timber stacks are still extra economical than concrete or steel. Compared to various other sorts of stacks, and relying on the source/type of hardwood, timber stacks might not appropriate for heavier lots. Secant heap walls are built such that area is left between alternative 'female' piles for the succeeding building of 'male' stacks. Construction of 'male' piles entails burning out via the concrete in the 'women' piles hole in order to essential 'male' stacks between. The male pile is the one where steel support cages are installed, though in some cases the female stacks are also reinforced.

Helical heaps are deep foundation components that are used to support brand-new structures or underpin existing foundations. They generate no resonances and can be set up with just 6 feet of overhanging area and in other limited-access circumstances. The stack shafts are made from galvanized steel and also are set up in short areas, each concerning 5- to 7-feet-long. Each stack consists of a lead helical area with bonded screw-like bearing plates; subsequent straight-shaft sections are mechanically-fastened to the lead section as it is advanced right into the ground. The piles are installed with a skid-steer or an excavator furnished with a high-power torque head, which is calibrated to straight correlate torque resistance with stack capacity. Helical stacks can likewise be installed with hand-held torque motors for locations that are not easily accessible with a skid-steer or small excavator.